Conflux is keeping rocket engines cool with 3D-printed heat exchange technology.

When a rocket blasts off for space, it generates exhaust gases that can reach thousands of degrees Celsius. These extreme temperatures pose risks to the vehicle’s structure, payloads, and occupants – so they need to be kept at a manageable level. In collaboration with German company Rocket Factory Augsburg, Geelong-based Conflux has created a small, lightweight heat exchanger designed to sit inside the gas duct of a rocket engine.

A heat exchanger is a device that takes the heat out of one fluid (either a liquid or a gas) by transferring it into a separate cold fluid. It’s a simple, efficient method of thermal management, and Conflux has a history of delivering heat exchangers for a range of uses – including industrial electronics, road and racing cars, and naval defence systems.

The company’s hallmark approach is additive manufacturing, also known as 3D printing. This allows tailor-made heat exchanger designs of unique shapes and sizes, using high-performance materials (such as Monel K-500 nickel-copper alloy on the rocket engine project), which are both compatible with the 3D printing process and durable enough for extreme applications.

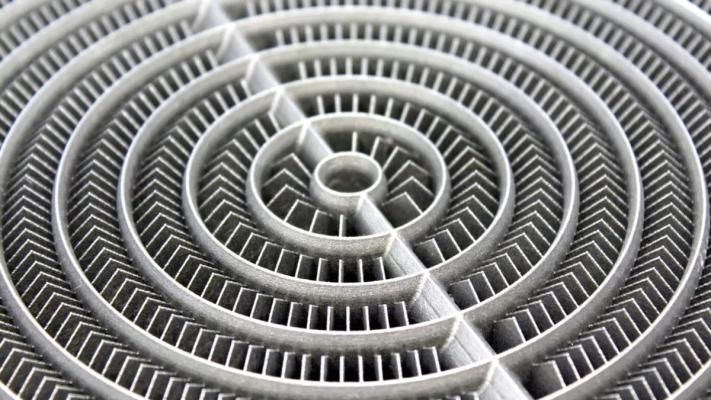

Heat exchanger printed in Monel K-500

Space applications see large changes in relative temperatures, densities, and viscosities of the working fluids throughout the heat exchangers. With additive manufacturing, we’re able to adapt our 3D surface geometry designs throughout our heat exchangers to optimise for the changing thermal-physical properties of the fluids.

~ Michael Fuller, Founder and CEO of Conflux.

Technology features

- 3D-printed metal heat exchangers with complex internal geometries for superior thermal performance.

- Utilises novel materials such as Monel K-500 alloy for high corrosion resistance and durability in rocket engine environments.

- Customisable designs enable rapid adaptation for various aerospace and space propulsion systems.

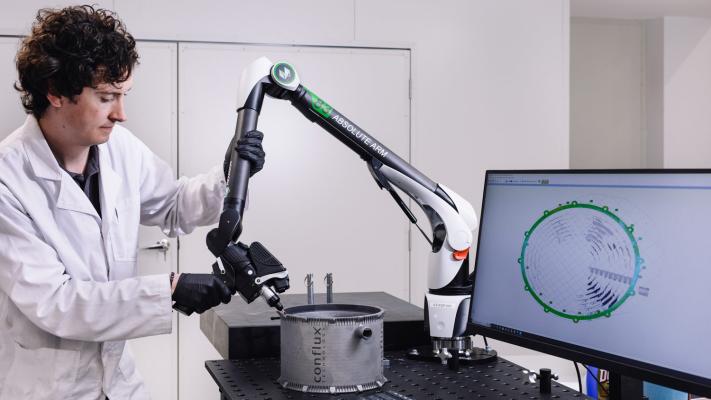

Pictured above: Performing quality checks on a 3D-printed heat exchanger with a virtual 3D model.

Project highlights

- Agency Moon to Mars grant awarded to develop heat exchanger and accelerate entry into global space markets.

- Heat exchanger technology delivered to Rocket Factory Augsburg, meeting customer requirements and performance targets.

- Scaling up serial production in Geelong, leveraging partnerships with Deakin University and Australian Nuclear Science and Technology Organisation.

Pictured above: An engine hot fire test.

Image credit: Rocket Factory Augsburg

Industry showcase

Australian space innovations making an impact.