Based in Melbourne’s east, Swinburne University is making a two-pronged contribution to Australia’s first lunar rover – by tackling the threats of dust and radiation on the Moon.

Swinburne is one of 10 universities in the Australian ELO2 consortium developing Roo-ver, and it’s home to a dedicated Space Technology and Industry Institute.

It also hosts a Space Robotics group preparing robots to meet extreme space challenges – using advanced mechanical and electronics workshops, plus a thermal vacuum testing chamber that can simulate sub-zero temperature conditions on the Moon.

Inside these cutting-edge facilities, Australian researchers are focused on protecting Roo-ver from two key dangers of the lunar environment: dust and radiation. At the same time, the measures they come up with could make a big difference to some important industries on Earth.

Dusting down

Know that nasty feeling of sand whipping into your legs on a blustery day at the beach? Well, imagine it being extra-sharp and almost impossible to clean off, and you’re some way to understanding the challenge of lunar dust.

The ‘dust’ in question is actually ultra-fine particles of lunar soil. These tiny specks are often beyond microscopic – even smaller than particles of smoke – but they cause big problems for astronauts and lunar vehicles.

Dr Michelle Dunn leads the Space Robotics group at Swinburne, and says the trouble begins with micrometeorite rocks showering the Moon.

“When micrometeorites reach Earth, we've got rain, we've got wind, and those things sort of take the corners off the dust,” Michelle says.

“But on the Moon, the dust stays sharp and jagged, it’s abrasive… if you try and wipe it off things, it scratches them.”

“Because we don't have an atmosphere on the Moon, the little electrons don't have anything to stick to, so the dust is statically charged… as soon as you send anything on Earth up there, it wants to stick to it.”

“So, the dust is this horrible, nasty thing – you send rovers up there and it just kills them over a couple of days.”

Neil Armstrong and his fellow Apollo 11 astronauts were the first people to discover the effects of lunar dust the hard way.

It invaded the joints of their space suits, causing them to jam, and quickly left scratches across their helmet visors.

“There's a very famous comparison of the Apollo space suit they used for years of training and the one they used for a couple of days on the Moon,” Michelle says.

“They put them side by side, and the one from the Moon was just so worn out, so much worse.”

Due to the small number of Moon missions in the decades since Apollo, progress on addressing the lunar dust problem has moved slowly.

However, with the advent of the Artemis program and Roo-ver drawing renewed attention to lunar dust mitigation, the pace is picking up – and the Swinburne team is excited to drive things forward.

A hi-trek solution

Michelle says there's two main methods of dealing with lunar dust.

“There’s what's called passive solutions, like coatings on things – I've got some students working on new coatings to go on surfaces to stop the dust sticking,” she says.

“Then there's active solutions, which are mechanical and electronic… I had a student who's now a doctor, Philipp Zanon, who developed this electrostatic field we can put onto an object to create this force field that dust is repelled by.”

Daniel Ricardo, a Postdoctoral Research Fellow working with Michelle, adds that the search for a solution is a matter of sustainability and longevity.

“Dr Zanon published a paper reviewing all the dust mitigation technologies used since Apollo, and the most effective one in terms of simplicity, cost, and effectiveness was just wet wipes,” Daniel says.

“In terms of durability – because you can't bring a million wet wipes up to the Moon – you need to think, can we use the energy we're getting from the sun to have a sustainable mitigation strategy for dust?”

“That's one thing that Michelle and myself and Philipp are looking at… how we can use electrostatics to create a force field, like in Star Trek, to repel dust from even getting onto the rover in the first place.”

Alongside the force field, the team is looking at how mission operations can help to address the problem as well. These approaches include having Roo-ver recognise and drive around big patches of dust, and taking a path that orientates with the sun to keep the force field charged up.

Radiation relief

Meanwhile, Postdoctoral Research Fellow Matt Large is working on ways to keep Roo-ver safe from harmful radiation, which can damage electronic components and stop the rover in its tracks.

Journeying into space means encountering what Matt calls a ‘mixed soup’ of charged particles – including electrons, protons, and heavy ions like uranium – and traditionally, metal shielding is used for protection.

“Aluminium is a very typical shielding material that we use in space… at the moment, Roo-ver will likely be a solid aluminium chassis,” Matt says.

“Sensitive electronics are then encased in further shielding… those core components that control the really pivotal functions for the Rover, like movement and data transmission and things like that.”

However, the task isn’t as simple as armour-plating the rover with beefy layers of aluminium. Thanks to years of research and data collection, particularly on board the International Space Station, scientists like Matt now understand that shielding comes with the risk of radioactive by-products that are even harder to handle.

“When these heavy, high-energy charged particles hit and interact with the aluminium, we have secondary radiation products that are produced,” Matt says.

“The destruction of that primary particle and explosion into all of these other parts can actually worsen the dose of radiation that both electronics and humans can receive.”

“So, sometimes shielding against these is as simple as putting more material between the space environment and what you want to protect… but sometimes putting more material can actually create a worse radiation environment internally, inside your spacecraft.”

Reinforcing from the inside out

The good news is Matt and his colleagues can use real-world data and knowledge built up over the decades to create computer simulations of the lunar environment Roo-ver is destined for. This helps them experiment and get creative in addressing the radiation challenge.

“It’s something we understand a little bit more clearly now with simulations and a lot more data, compared to the Apollo times… we have so much more readily available experimental data that then feeds these models that we can use to make more accurate predictions.”

“One thing we're very interested in is using components already inside the rover, and inside the electronics, and simply just shifting or changing their location to potentially reduce the radiation dose they receive – without massively changing the design or adding extra material to the rover.”

“Another thing is electronics manufacturers can in some instances make specialised components that are more resistant to radiation, and will have better longevity in space.”

Benefits back on Earth

While the Swinburne team is making a valuable contribution to the management of dust and radiation exposure on the Moon, the advancements created through their work will also be useful on Earth.

For example, a key focus of Michelle’s team is keeping solar cells free of dust with minimal resources.

“If we can get our dust mitigation solution working on solar cells on the Moon, we can definitely do that here on Earth as well,” Michelle says.

“We can have solar cells self-cleaning during the day, and improve the amount of energy we’re able to harvest.”

Meanwhile, Matt points to the crossover between space radiation exposure testing and everyday medical facilities as an immediate example of knowledge transfer.

“A lot of our testing is with joint-use medical facilities… so that’s a very direct translation there, by bringing additional information that we get back to Earth,” Matt says.

“A lot of the radiation detectors we use to accurately measure how much radiation we're delivering, and what sort of radiation environment this shielding creates inside our spacecraft, are the same sort of detectors we'll use to monitor patient outcomes during testing for cancer treatments.”

In addition, he’s optimistic that the radiation shielding advancements he’s working on for Roo-ver will unlock new treatment options for cancer patients in Australia.

“For a little while now, Australia has been pushing for proton beam therapy applications – where you treat cancer not just with electrons and X-rays, but also with protons – and some of the limitations for that are shielding,” Matt says.

“Protons create a much more intense radiation environment… they're a lot harder to shield against when you're treating a patient, so that's a potential application for this shielding.”

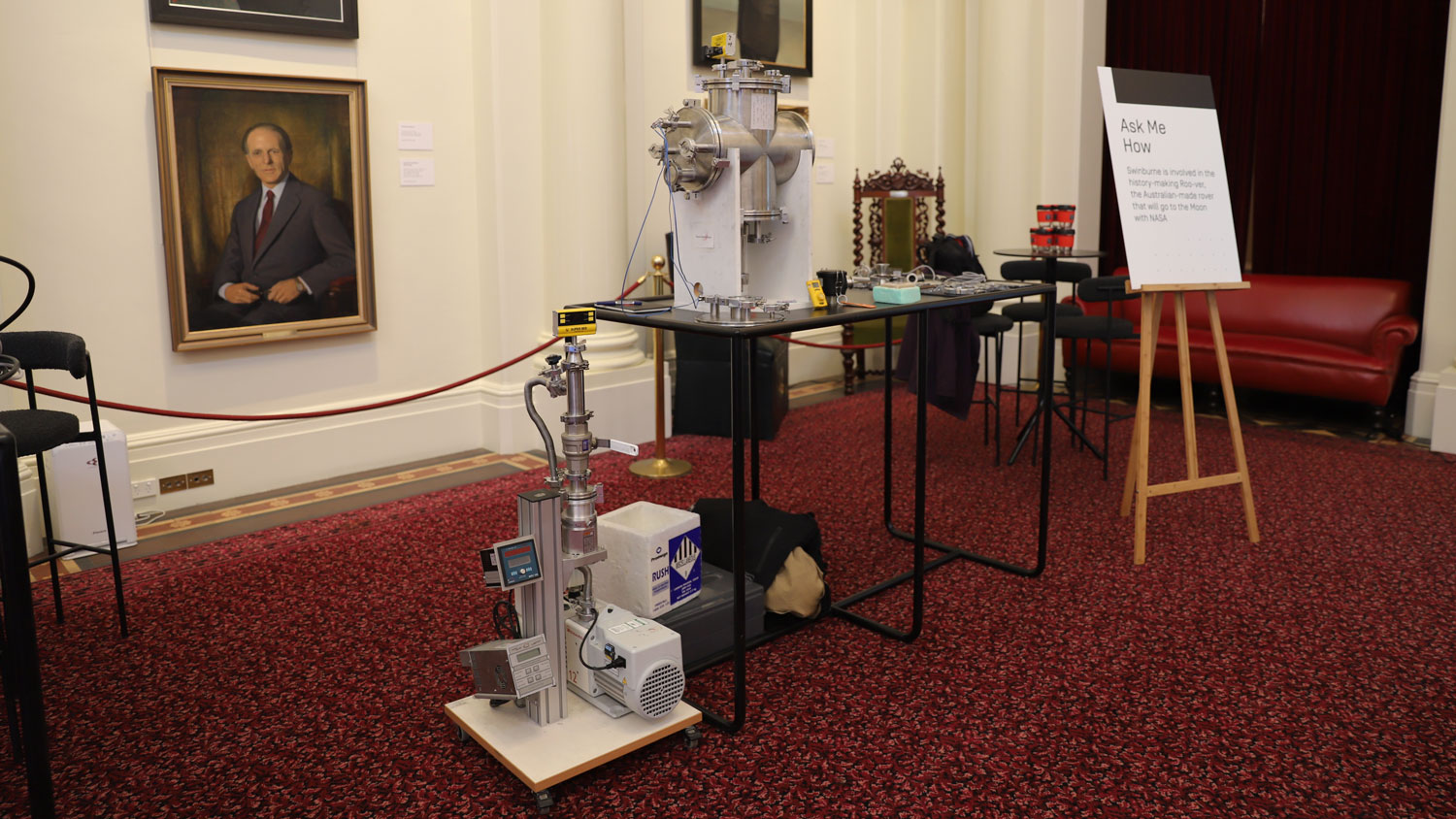

Industry showcase

Increasing national capability, responsibly

Main image caption: (L-R) Daniel Ricardo, Michelle Dunn, and Philipp Zanon at Victoria's Parliament House in Melbourne | Credit: Swinburne University.